Steel wire rope, as an important load-bearing and traction tool, is widely used in many fields such as construction, bridge construction, lifting and transportation, mining, and navigation. The question of whether steel wire ropes have elasticity is an interesting topic involving materials science and engineering mechanics. In fact, steel wire ropes do have a certain degree of elasticity, which is crucial for their performance in various applications.

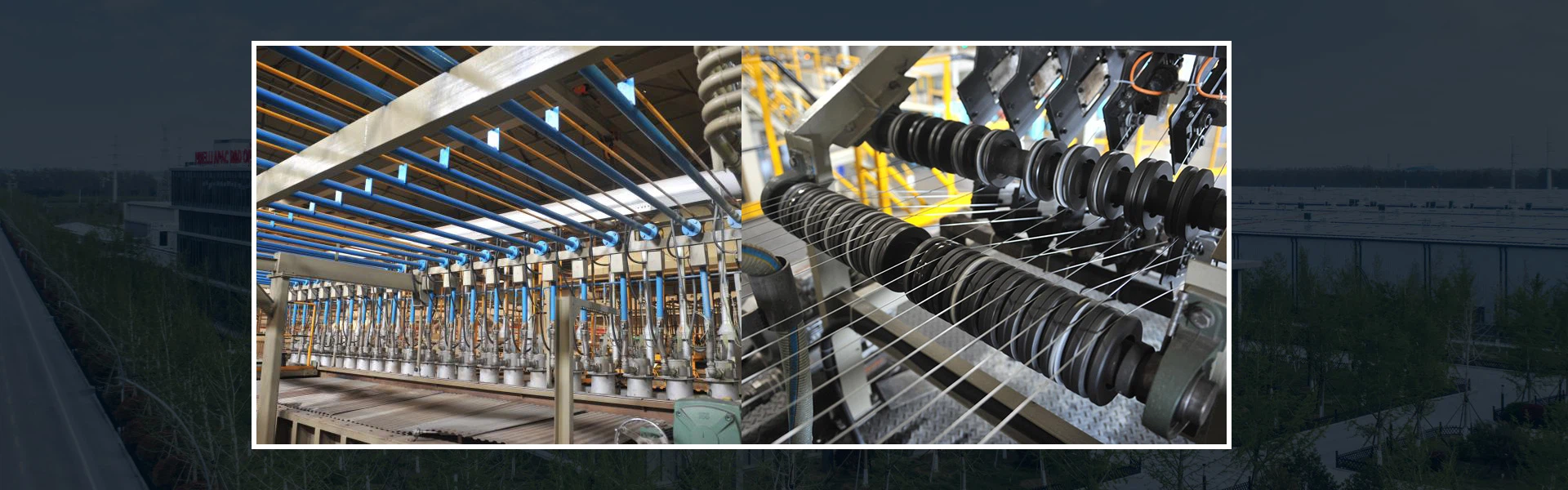

A steel wire rope is usually made by spiral winding multiple strands of fine steel wire around one or more central core wires (which may also be fiber rope cores). This structural design not only enhances the strength of the steel wire rope, but also endows it with a certain degree of flexibility and elasticity. Each steel wire itself, due to the properties of the material (mainly the elastic modulus of steel), will experience slight elongation after being subjected to force. When the external force is removed, it can be restored to its original length, which is the basis for the elastic performance of steel wire ropes.

The physical principles of elasticity

Elasticity is the ability of solid materials to undergo deformation under external forces, and to fully or partially restore their original state when the external force is removed. For steel wire ropes, their elasticity comes from the elastic properties of the steel materials that make up them. According to Hooke's law, as long as the external force does not exceed the elastic limit of the material, there is a linear relationship between stress and strain, that is, stress (force per unit area) is proportional to strain (deformation per unit length). This means that when the steel wire rope is subjected to tension, its elongation follows a certain proportional relationship with the tension it is subjected to.

The practical significance of elasticity

The elastic characteristics of steel wire ropes are of great significance in practical applications. Firstly, it enables the steel wire rope to absorb impact and vibration through its own small expansion and contraction while carrying the load, protecting the suspended object from damage and reducing the impact on the fixed point. Secondly, elasticity helps to disperse the load, allowing multiple steel wires to jointly bear the force, improving the overall bearing capacity and safety. Furthermore, under dynamic load conditions, such as during crane lifting operations, elasticity can cushion the instantaneous force changes and avoid the risk of sudden fracture.

Elastic considerations

Although steel wire ropes have elasticity, several key factors still need to be considered in the design and use process. One is the elastic range, which refers to the amount of elongation that a steel wire rope can safely withstand during normal use. The second is elastic recovery. Will the elasticity of the steel wire rope weaken due to fatigue after long-term stress. The third is environmental factors, such as temperature changes, corrosion, etc., which can affect the elasticity and service life of steel wire ropes.

In summary, steel wire ropes do have a certain degree of elasticity, which is determined by their material characteristics and structural design.